The automatic air filter paper filling machine is one of the key equipment in the large air filter production line. It is mainly used to automatically and efficiently load the filter material onto the folding machine or laminating machine to ensure continuous production, reduce manual intervention, and improve production efficiency and consistency. 1. Equipment functions and features Automatic feeding: It can be connected to the coil unwinding system to automatically feed the filter material into the folding or compounding process to reduce manual handling. Precise positioning: Photoelectric/ultrasonic sensors are used to detect the edge of the filter material to ensure accurate positioning and avoid deviation. Tension control: Equipped with servo motors or magnetic powder brakes to maintain stable tension of the filter material to prevent stretching or wrinkling. Quick material change: Supports non-stop material splicing (such as overlap or hot melt), reducing downtime and improving production efficiency. Strong compatibility: It can adapt to filter materials of different widths (such as 300mm~2000mm) and materials (glass fiber, PP, PET, etc.).

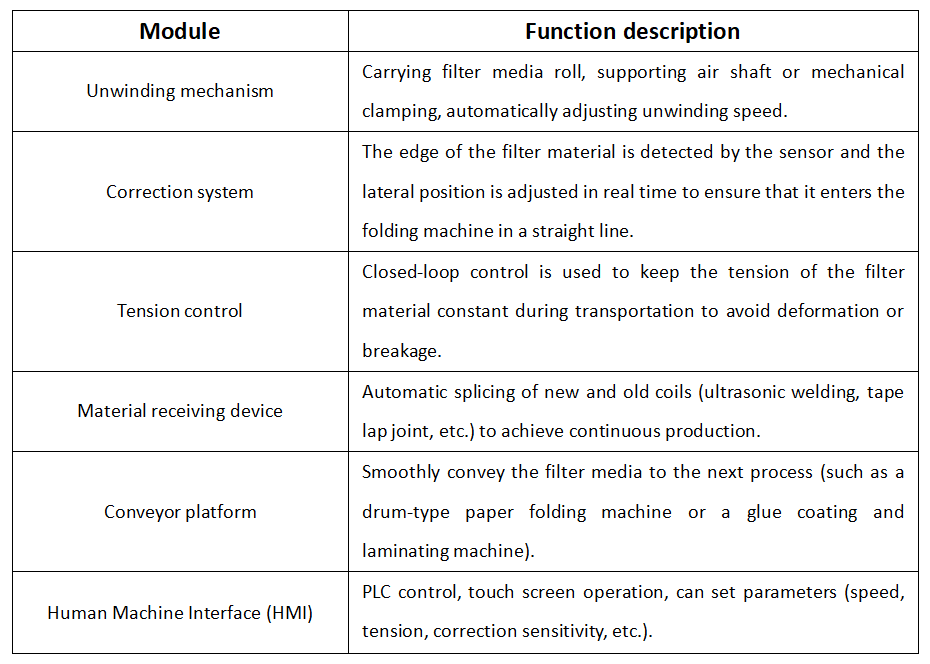

2. Core structure

3. Workflow

(1) Automatic roll-up: The mechanical arm or lifting platform loads the filter material roll onto the unwinding shaft.

(2) Material positioning: The filter material head is automatically pulled to the material receiving position and the edges are aligned.

(3) Tension adjustment: Set the appropriate tension according to the filter material characteristics (such as gram weight, elasticity) to avoid stretching or relaxation.

(4) Continuous feeding: The straight line is maintained through the deviation correction system and enters the paper folding machine or laminating machine.

(5) Automatic material splicing: When the old roll is used up, the splicing device automatically splices the new roll to ensure uninterrupted production.

4. Industry Applications

HVAC air filters: used for industrial/industrial air conditioning filter production.

Automotive air filters: engine air intake filters, cabin air filter manufacturing.

5.Advantages

Improve efficiency: 3~5 times faster than manual loading, suitable for mass production.

Reduce waste: Precise tension control reduces material loss (such as glass fiber breakage).

Stabilize quality: Avoid deviation or contamination caused by manual operation.

6.Selection and maintenance recommendations

Key points for selection:

Match the filter material width, weight and production line speed.

Choose a suitable material joining method (such as hot melt for PP filter material).

Maintenance focus:

Clean the deviation sensor regularly to prevent dust interference.

Check the wear of the tension roller to avoid affecting the accuracy.

The automatic air filter paper filling machine is the “intelligent porter” of the large air filter production line, ensuring that the filter material enters the subsequent processing link efficiently and accurately, and is an important equipment for realizing automated production. With the development of Industry 4.0, some high-end models have integrated IoT functions, which can monitor the equipment status in real time and optimize production parameters, further improving the level of intelligence.

Post time: Jul-10-2025