Products

-

Full-Auto Turntable Clipping Machine

The machine uses compressed air as the power source to automatically clamp and cut off the blanking material.

- Folding height: 9.5mm~35mm

- Filter height range: 40mm~250mm

- Production efficiency: 20pcs/min~35pcs/min

- Usable metal strip thickness: 0.25mm

- Loadable metal strip width: 12mm

- Feeding motor power: 1KW

- Turntable motor power: 1.5KW

- Metal strip feeding motor power: 0.12KW

- Power supply: 220V/50HZ

- Air pressure: 0.6MPa

- Dimensions: 2300*1300*1500mm

-

Full-Auto end cap gluing Machine

This machine is used to dispense the up and lower end caps of the spin-on filter elements.

- End cap diameter range: 60-100mm

- Speed: 50pairs/min

- Adhesive type: PVC (high temperature curing)

- Power supply: 380V/50HZ

- Conveyer motor power: 0.75KW

- Air pressure: 0.6Mpa

- Equipment weight: 400KGS

- Dimensions: 1600*1100*1400mm

-

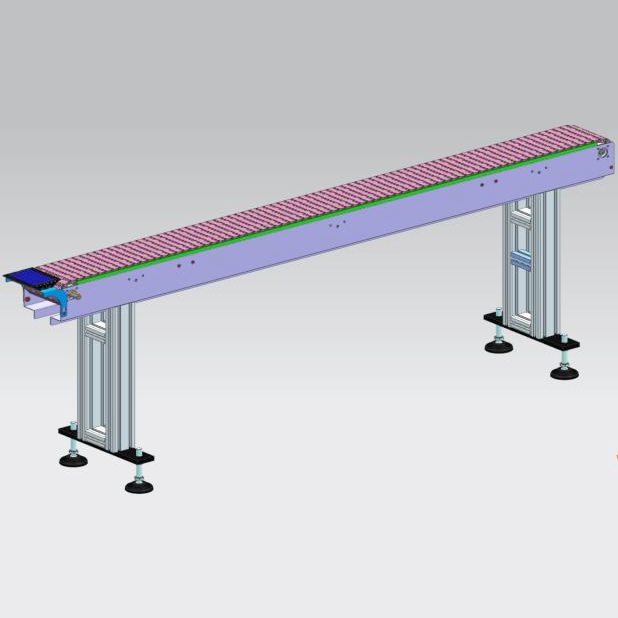

PVC conveyor belt

Used for transporting semi-finished filter core

Length:10m

Width:0.4m

Nose motor 750W

(Frequency converter speed regulation) aluminum alloy frame -

Automatic anaerobic gluing machine

Used for evenly applying anaerobic adhesive to the filter cartridge chassis cover plate

- Product effective diameter: φ80~φ160mm

- Production efficiency: 20~30 pieces/minute

- Motor power: 90 watts

- Working voltage: 220 volts/50 hertz

- Working air pressure: 0.3 MPa

- Dimensions: 1000*600*1450 (mm)

- Machine weight: 130 kg

-

Automatic filter sealing machine

Used for tightly fitting the filter cartridge chassis and the housing

- Production capacity: 42 pieces/minute

- Sealing diameter: φ95mm

- Applicable steel plate thickness: 0.6mm

- Height of sealing parts assembly: 50-360mm

- Number of equal parts of turntable: 12 equal parts

- Motor power: 4 kW

- Working air pressure: 0.6 MPa

- Working voltage: 380 volts/50 hertz

- Machine weight: 1000 kg

- Dimensions: 1100*800*2100 (mm)

-

Automatic wiping machine

To wipe the oil on the seal

- Conveyor belt motor power: 370 watts

- Edge banding belt motor power: 200 watts

- Servo motor power: 350 watts

- Working voltage: 220 volts/50 hertz

- Working air pressure: 0.3 MPa

- Machine weight: kg

- Dimensions: 1550*1000*1450 (mm)

-

Bidirectional buffer strip 3 meter

When the material conveyor belt is fully loaded, the filter is buffered and waiting on this equipment

- Buffer belt width: 465mm

- Working voltage: Working voltage

- Motor power: 200 watts

- Inverter power: 1.5 kW

- Machine weight: kg

- Dimensions: 3000*630*750mm

-

Automatic leak detection machine

This equipment is used to test the air tightness of the filter when it is exposed to water

- Production speed: 40 pieces/minute

- Product effective diameter: φ60mm~φ105mm

- Product effective height: 60mm~130mm

- Flip motor: 1.5 kW

- Product station: 8

- Conveyor belt motor: 200 watts

- Working air pressure: 0.6 MPa

- Working voltage: 220 volts/50 hertz

- Machine weight: kg

- Dimensions: 2350*1500*1900 (mm) without opening the flip cover, the alarm light does not bend

-

Plastic parting conveyor belt 1 METER

Used for material handling before the filter enters the automatic leak detector to prevent material congestion on the conveyor platform.

- Material belt width: 152mm

- Working voltage: 220 volts/50 hertz

- Motor power: 250 watts

- Control method: Speed control box control

- Machine weight: kg

- Machine size: 1000mm*320mm*750 (mm)

-

Leak detection drying line 6METERS

Used for drying and transporting the filter after water sealing detection and moisture drying treatment.

1. The total length of the baking channel is 6000mm, the length of the baking channel is 4000mm, the front part is 500mm high-pressure water blowing, and the length of the rear conveyor line is 1500mm.

2. The conveyor belt is 750mm wide and the belt plane is 730±20mm above the ground. Frequency conversion speed regulation 0.7-2m/min, output 20 pieces/min.

3. Infrared heating tube is used for heating, with a heating power of about 30KW and a total power of about 28KW. The preheating time in winter room temperature is no more than 15 minutes, and the temperature can be adjusted to 160°C.

4. There is also a fan cooling at the exit, 65W*6 length 0.7m. -

Bidirectional buffer strip 1.5meter

Used for buffering and flowing the filter on the assembly line.

- Buffer belt width: 465mm

- Working voltage: 220 volts/50 hertz

- Motor power: 200 watts

- Inverter power: 1.5 kW

- Machine weight: kg

- Dimensions: 1500*630*750mm

-

Bottom plastic film sealing machine

Used for sealing the bottom surface of the filter to prevent dust and other stains from entering the filter product after it is made.

- Product effective diameter: φmm~φmm

- Product effective height: mm~mm

- Film size: width 170mm*thickness 0.05mm

- Hot air blower power: 3.5 kW

- Production speed: pieces/minute

- Working voltage: 380 volts/50 hertz

- Working air pressure: 0.6 MPa

- Machine weight: kg

- Dimensions: 2200*1650*1650 (mm)

-

Phone

-

E-mail

-

Whatsapp