End cover glue injection machine

Key electrical components brand

HMI:WECON

PLC:XINJE

Servo:VEICHI

Low voltage component:DELIXI

Pneumatic components :AirTAC Somle OLK

Frequency converter:VEICHI

Electrical motor:HEBEIYANDE

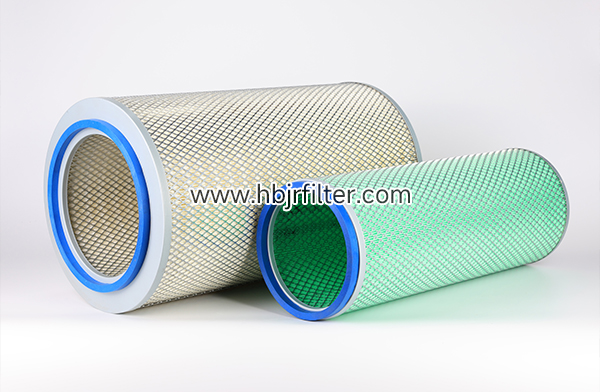

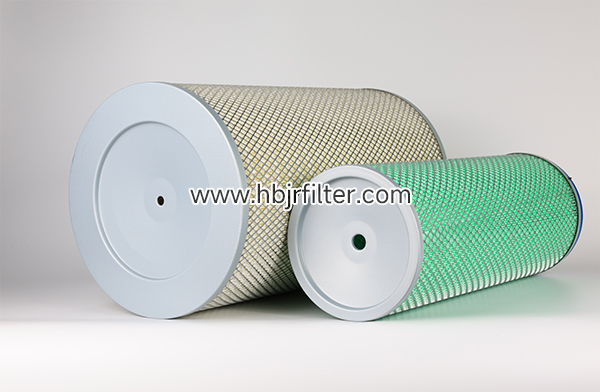

Finished Products

Product Features

Introducing the Filter Cap Gluer, the ultimate solution for your filter cap manufacturing needs. This machine is ideal for businesses, regardless of size, who wish to increase production efficiency while maintaining consistent product quality.

With adjustable turntable speed and gluing speed, you can easily adjust the settings according to the size of the filter cap, ensuring accurate and precise gluing process. The amount of glue applied to the machine is uniform and reliable, ensuring consistent and perfect finishing every time.

The filter screen gluing machine adopts a stepping motor control system, with fast gluing speed, less rework time and high productivity. Fast return times ensure the machines can handle any high-volume needs, while high production rates ensure you can deliver products on time.

The composite tank of the screen glue applicator is equipped with a thermal stirring function to keep the glue at a constant temperature, thus ensuring better glue application every time. In addition, the machine has its own circulation system, which prevents material from settling. This feature ensures that the quality of the glue remains consistent, resulting in a consistent and reliable product.

The filter glue applicator's tubing features self-regulating heating to ensure the glue stays within the ideal temperature range, even in cold temperatures. The self-controlled temperature ensures that you don't have to worry about temperature adjustments, saving you time and resources.

A filter cap applicator is a cost-effective solution for any business looking to increase the quality of filter cap production without sacrificing productivity. The machine is easy to operate and maintain and offers unrivaled quality, ensuring your product is consistent and of the highest quality.

In conclusion, the filter cap gluer is the ultimate solution for your filter cap production needs. It is efficient, reliable and cost-effective to ensure the success of your business and provide your customers with high-quality products. Take your business to the next level by investing in a cover filter applicator.

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.