Rotary type air filter paper folding machine

Key electrical components brand

HMI: WECON

PLC: XINJE

Servo: VEICHI

Low voltage component: DELIXI

Pneumatic components: AirTAC Somle OLK

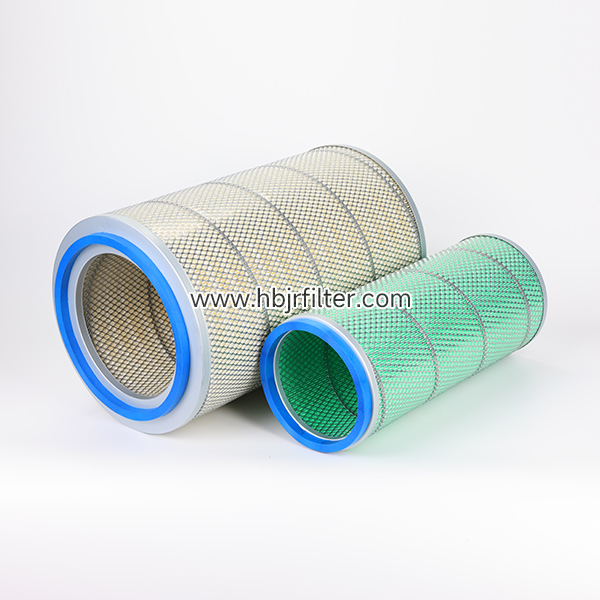

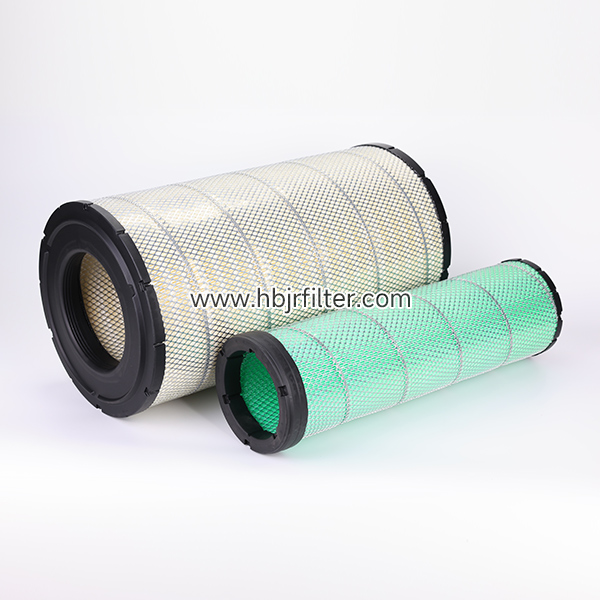

Finished Products

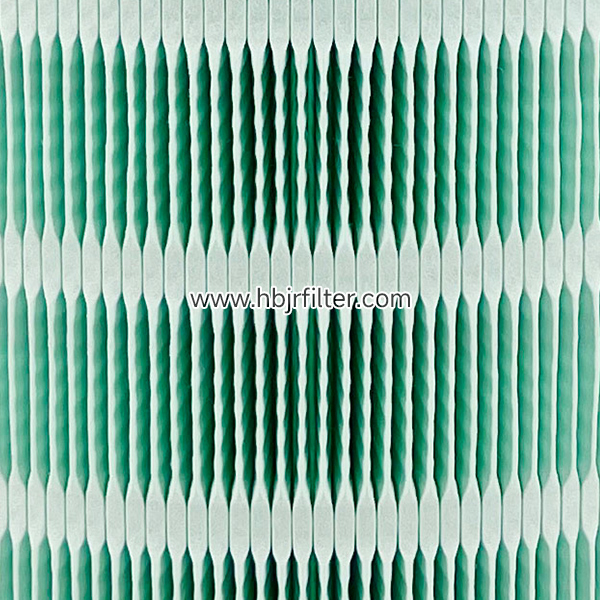

Product Features

Introducing the Model 700 Drum Air Filter Folder, a state-of-the-art machine designed to revolutionize the production of air filter folds. This cutting-edge machine has a wide range of functions and features to increase efficiency and simplify production processes.

Automatic paper feeding ensures a seamless workflow for non-stop continuous operation. Pneumatic cutting function guarantees precise and accurate cutting, ensuring uniform paper size. Say goodbye to manual counting as this machine does it for you, eliminating the risk of human error and saving valuable time.

Humidification and preheating functions are integrated in the machine to optimize paper quality. By maintaining optimum humidity and temperature, the paper is perfectly formed for enhanced air filtration. The automatic rewind function neatly organizes the folded sheets, ready for further processing.

The addition of a chain conveyor facilitates the movement of the paper throughout the production process. This seamless transfer eliminates the need for manual handling, reducing the risk of damage and reducing reliance on labor. In addition, the heating and forming function ensures that the paper is formed correctly in one step, further increasing production efficiency.

The Model 700 Drum Air Filtered Folder is an industry game changer that combines cutting-edge technology and automation to revolutionize the folding paper production process. With its advanced features and functions, it promises to increase productivity, reduce labor costs and provide excellent paper quality.

In conclusion, the Model 700 Drum Air Filter Folder is the perfect solution for companies looking to optimize their air filter production. The machine has the functions of automatic paper feeding, pneumatic cutting, counting, humidification, preheating, automatic winding, chain conveying, heating and setting, etc., which simplifies the production process, improves the output, and ensures the consistent high quality of folding paper. Embrace innovation today and experience the efficiency and reliability of the Model 700 Roller Air Filter Folder.

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.