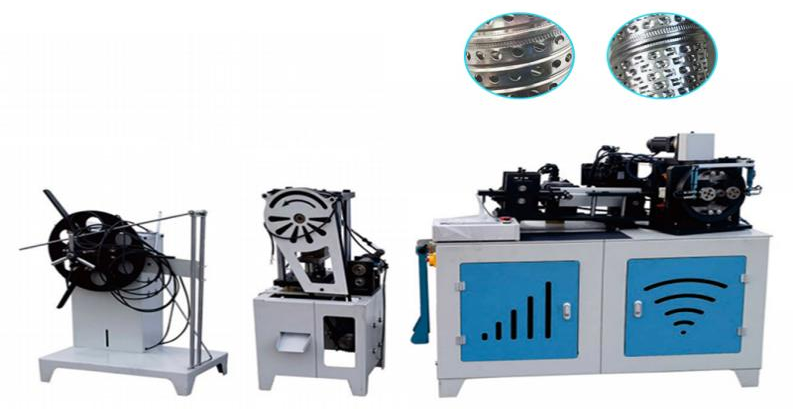

Central tube making machine

Product Features

Introducing our revolutionary product line, designed for the production of inner center hall networks of diesel engines. Our state-of-the-art equipment includes automatic feeding racks, high-speed punches and center tube winders, all engineered to simplify your manufacturing process and improve the quality of your diesel engines.

The first thing to transform your production line is our automatic feeding rack. This innovative rack is precision engineered to ensure a seamless and efficient infeed system for your manufacturing process. With its automation capabilities, you can say goodbye to manual labor and hello to higher productivity. By reducing human error and optimizing material handling, our automatic feed racks guarantee consistent and reliable performance.

Next up are our high-speed presses, designed to meet the demanding demands of diesel engine production. Equipped with cutting-edge technology, our high-speed punch presses deliver exceptional speed and precision, enabling you to achieve exceptional precision with every punch. Say goodbye to inefficiency and hello to a fast, flawless punching experience that saves you time and money while maximizing your output.

Center tube winders complete our comprehensive product line. Specifically designed to meet the complex demands of diesel engine production, our center tube winders take coil forming to new heights. With its advanced features, you can effortlessly and precisely shape the coil, ensuring optimum performance and durability of your engine. Experience increased productivity and reliability with this vital part of your production process.

At [Company Name], we understand the importance of efficiency and quality in your manufacturing operations. That's why our innovative product line is engineered to meet every aspect of your engine production needs. By integrating our automatic feed racks, high-speed punch presses and center tube winders into your manufacturing process, you can increase productivity, improve quality and save significant costs.

Invest in our cutting-edge technology and embark on a transformative journey to excellence in diesel engine production. Experience the future of engine building with our revolutionary product line. Contact us today to discover how our state-of-the-art equipment can revolutionize your business.

Key electrical components brand

HMI:WECON

PLC:XINJE

Servo:VEICHI

Low voltage component:DELIXI

Pneumatic components :AirTAC Somle OLK

Application

The production line is applied to auto tri-filter industry, hydraulic pressure, purification and water treatment industries, etc.